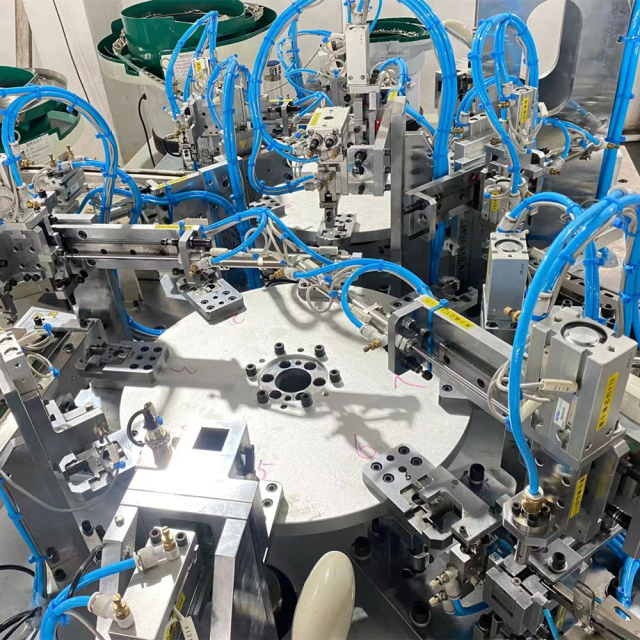

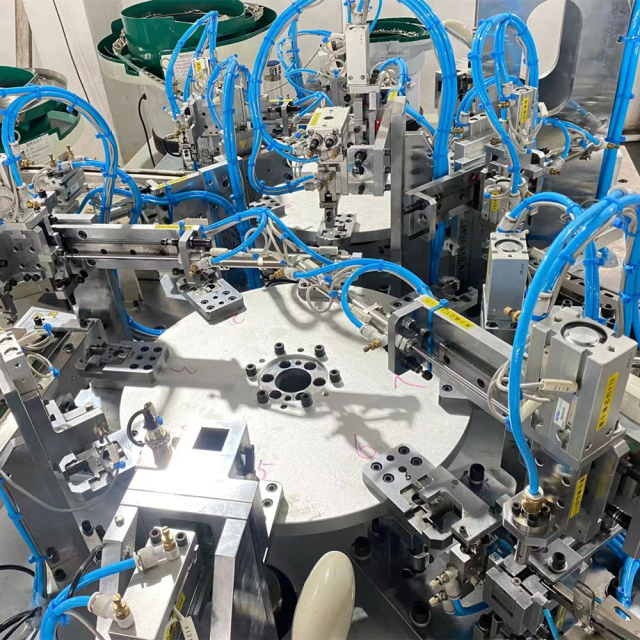

| Configuration | Brand | Configuration | Brand |

| Air cylinder | Taiwan AirTAC | Cylinder induction line | Taiwan AirTAC |

| Slicer | China ZXB | Touch screen | WEINVIEW |

| PLC | Japan Mit-subishi | Feeder | China origin |

| Riverting | China origin | Air pressure gauge | Taiwan AirTAC |

| Servo motor | Taiwan Delta | Frequency converter | Japan Mit-subishi |

| Slide | Taiwan HIWIN | Oil pump | China origin |

| Stepper motor | Magnetic valve | Taiwan AirTAC |