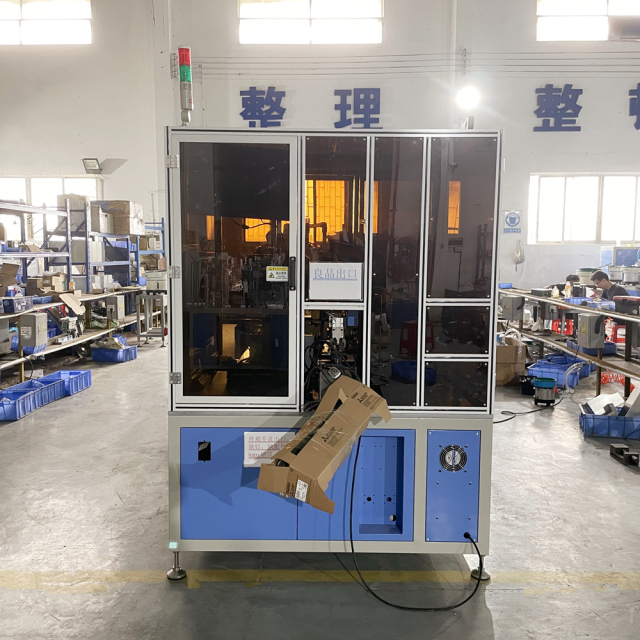

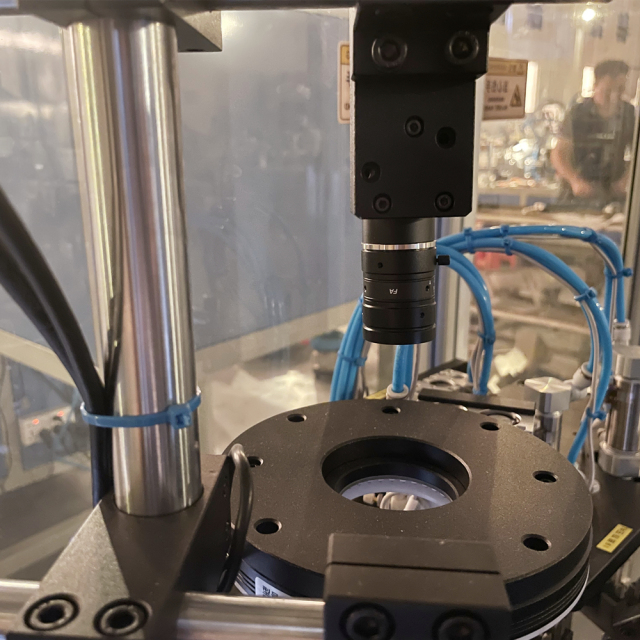

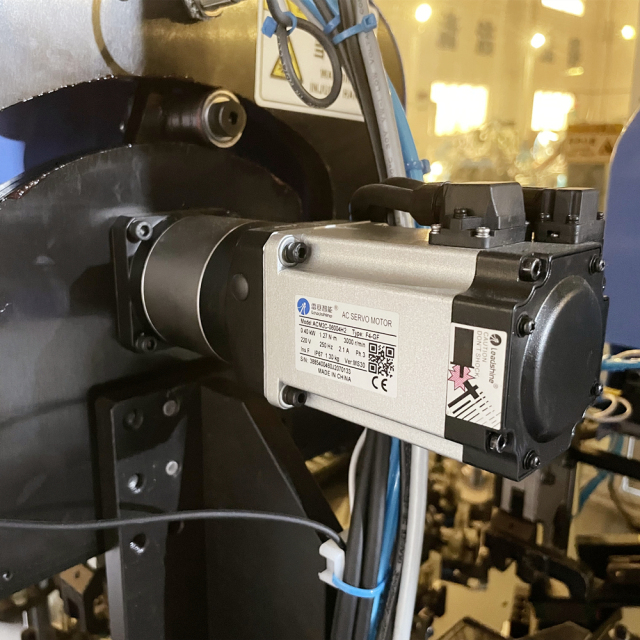

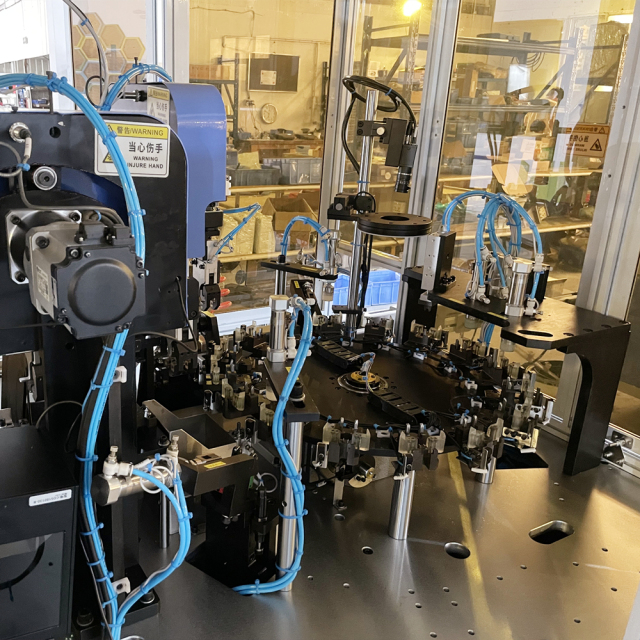

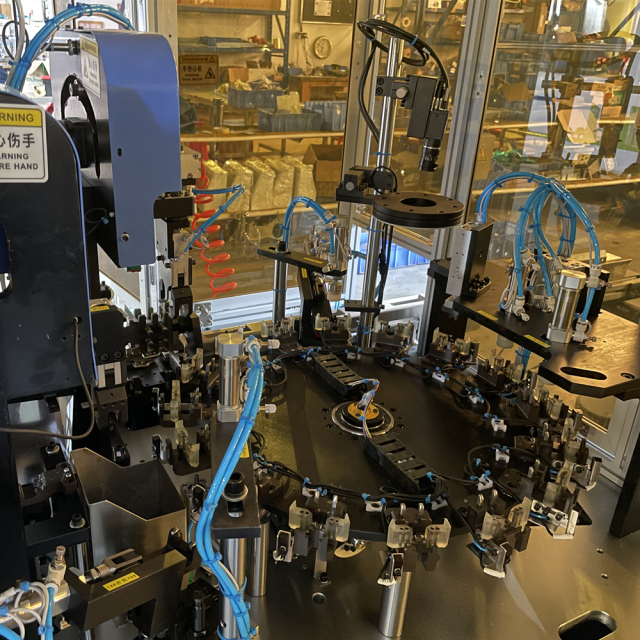

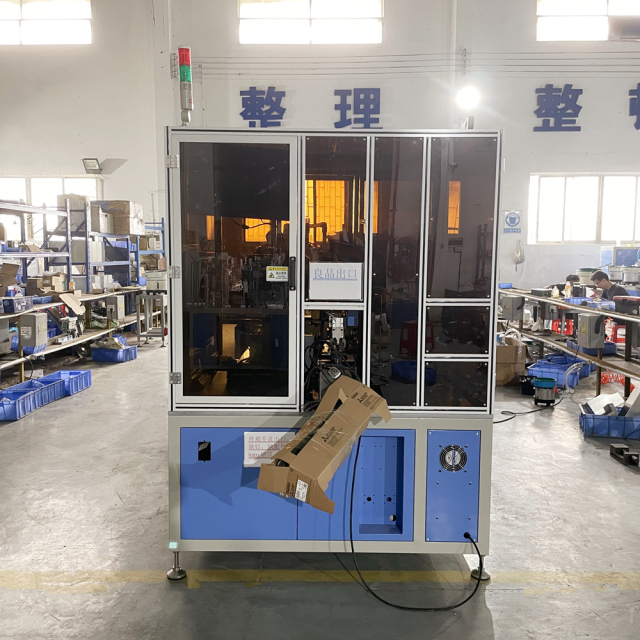

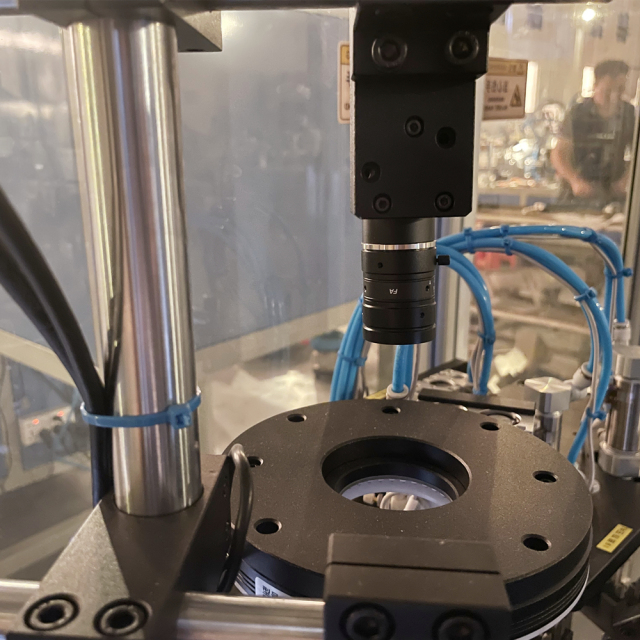

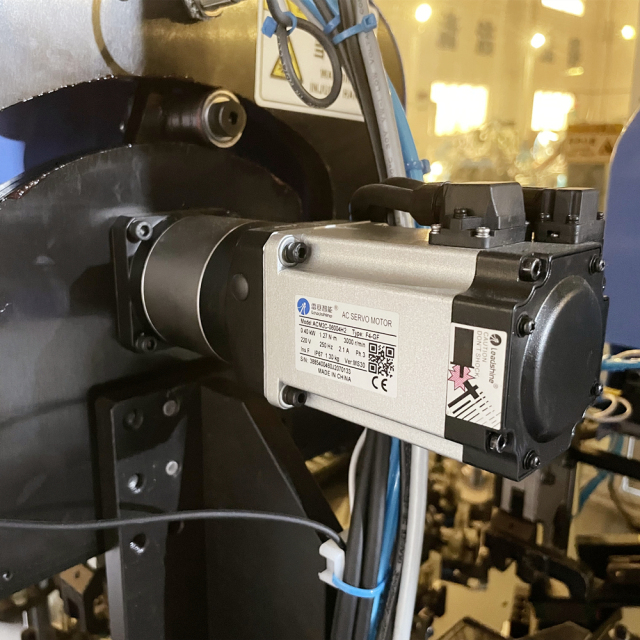

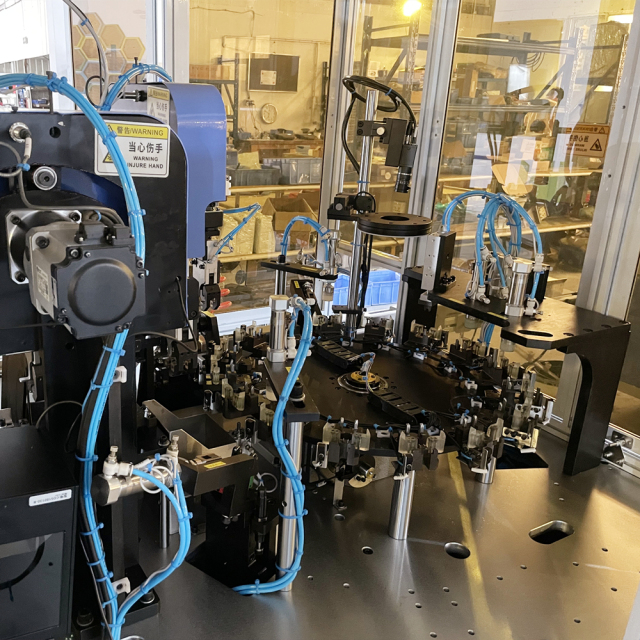

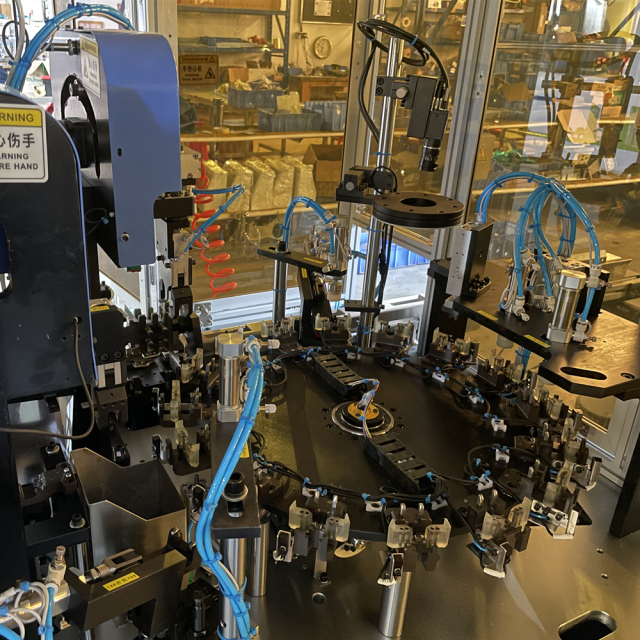

This equipment is specifically designed for the four sided detection of scratches, missing parts, mixed labeling, electroplating defects, and closing time on the appearance of hardware cabinet hinge. The equipment’s efficiency production is 18000 pieces/10 hours,the CCD visual cameras is 12 million pixels.There are 3 cameras are paired with 1 set industrial control system (with a reserved installation position for the fourth camera).

When the dimensional accuracy requirements of visual inspection are raised during the production process, and the qualified rate of the detected good product itself reaches 100%, that is, there are no defective products in the good product.If there will be approximately 3% of the defective products, which is among these 300 defective products among 10000 product, but in face only 50 may be true defective products, and the other 250 may be good products. These 300 pieces need to be manually selected or tested and sorted again on the machine! The above defective product data is only for reference, and the actual data is related to the qualification rate of the product itself.

Introduction to device parameters and functions:

1.inspect hinge cup mix labeling,hinge cup hole dimension(45/48/52)

2.Inspect hinge cup 3mm higher the side,and no damage

3.Detection and discrimination insert arm,half overlay arm and full overlay arm.

4. Height of adjusting screw 2.5+0.5/-0.5 or 2.0+0.5/-0.5 can be detected.

5.The adjusting screw is not skewed(degree from 3°~-1°)

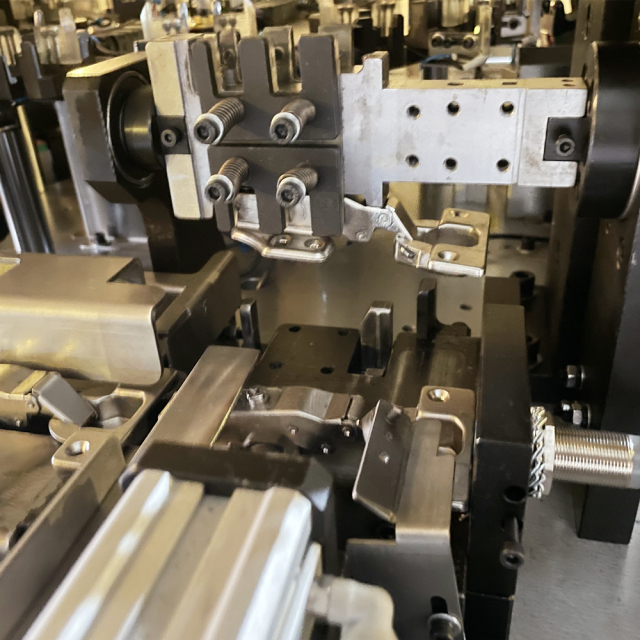

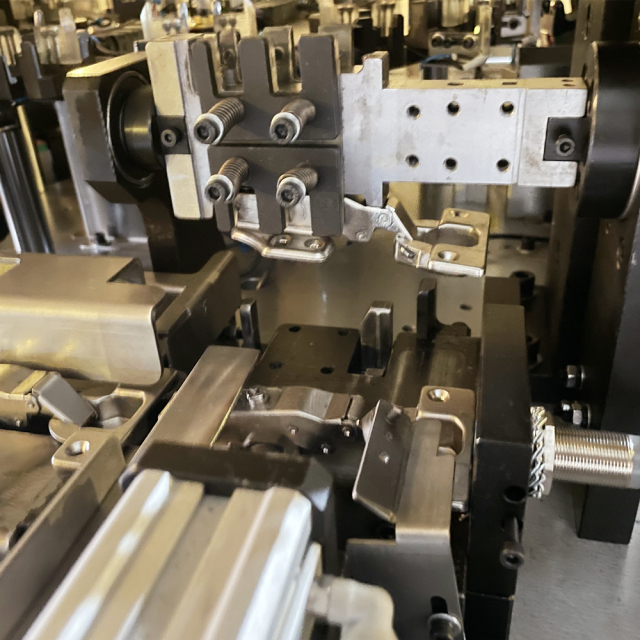

6.The end buckle is flexible and has a certain degree of rebound force when pressed

7.No cracking on the side of the 23.5 wide hinge cup

8.Detected the U pin on the right position,hinge cup no split.

9.The riveting on the hinge arm should be flat,there is no riveting missing or half riveting.

10.The specifications of the hinge cup opening on the back of the product are inspected, and there are no cracks in the lamination.detected if the rubber parts are missing The visible side at the bottom of the hinge arm can be inspected, while the internal side of the hinge arm cannot be inspected

11.Detected the hydraulic damper,triangle part and I pin total length,and the I pin position is right(to determine whether there is riveting)

12.The closing time of the detection product is 3-7 seconds (adjustable time), and the closing is fast without failure. The sensing distance of the detection closing sensor is 2mm.

13.Is there any detectable eccentricity screw (or base screw)