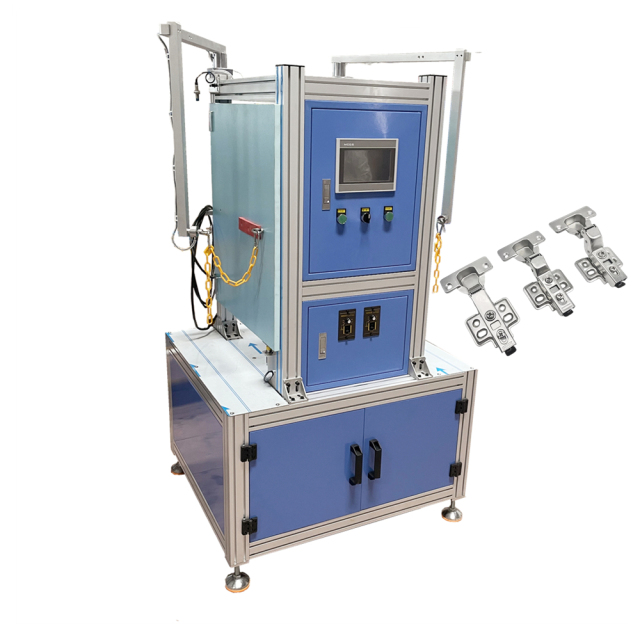

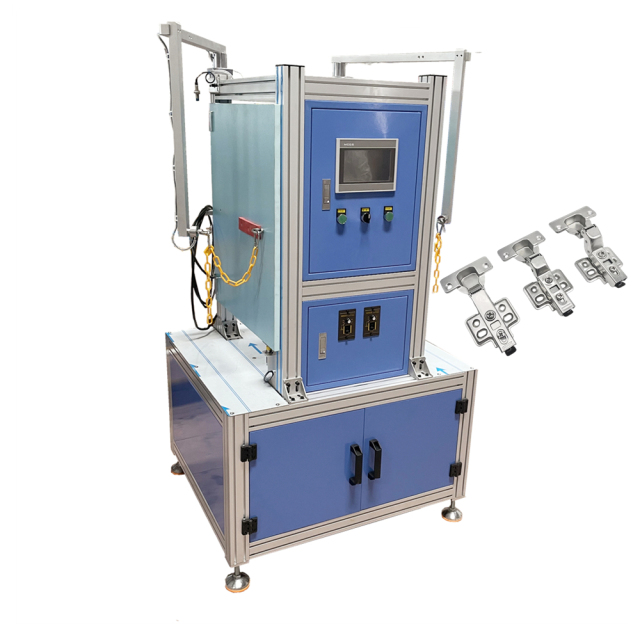

Cabinet hinge life cycle testing machine

1.-Purpose of the durability testing machine for finished door,cabinet door hinge fatigue life testing machine is: This machine is suitable for testing the durability and fatigue of cabinet door hinge opening and closing.

2-

3-Equipment structure

(1)The entire machine adopts an aluminum profile frame structure of 60 * 60 aluminum profile frame, imitating the installation method of double door and double wardrobe hinges. Each corresponding installation fixture is equipped at the hinge of the cabinet wall and door.

(2)The cabinet door is made of 700mm * 600mm * 19mm peach blossom solid wood laminated board, with a weight of 5KG that meets national standards. The center of the door panel is drilled, and a weight of 3KG can be hung on both sides for load-bearing testing. The distance between the hinge pocket and the upper and lower sides of the door is 50mm. Mechanical adjustment of the 0-120 degree eccentric disc mechanical arm opening and closing device, with a 30 degree buffer reserved before and after

(3)Votage:220V,50HZ

4-Equipment performance and display

(1) Speed regulation of potentiometer. The opening and closing time can be adjusted according to the opening and closing angle of 100 degrees, 5 seconds to 8 seconds (the standard is that the opening and closing time are about 3s, and the recommended maximum frequency is 10 times/min, except for damping). Opening and closing times: electronic digital display 0-999999.

(2)