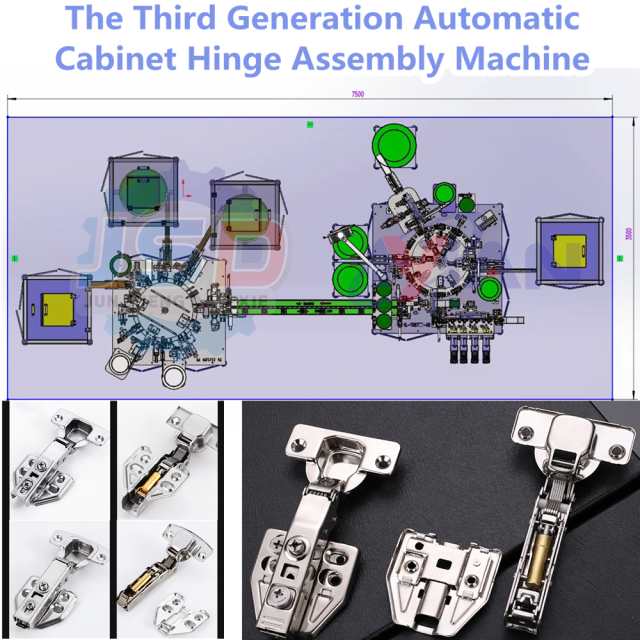

1-Equipment Characteristic and advantages

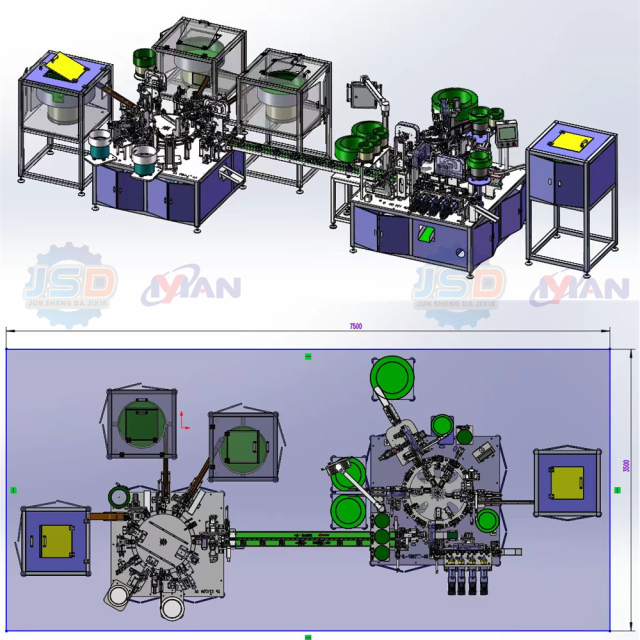

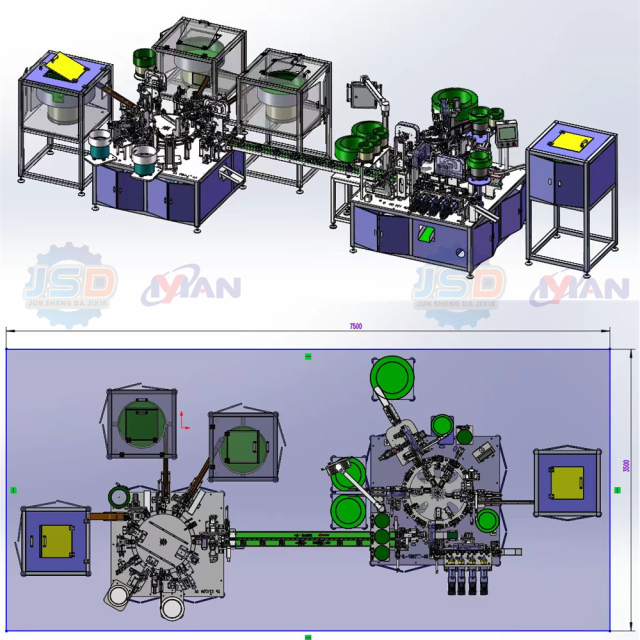

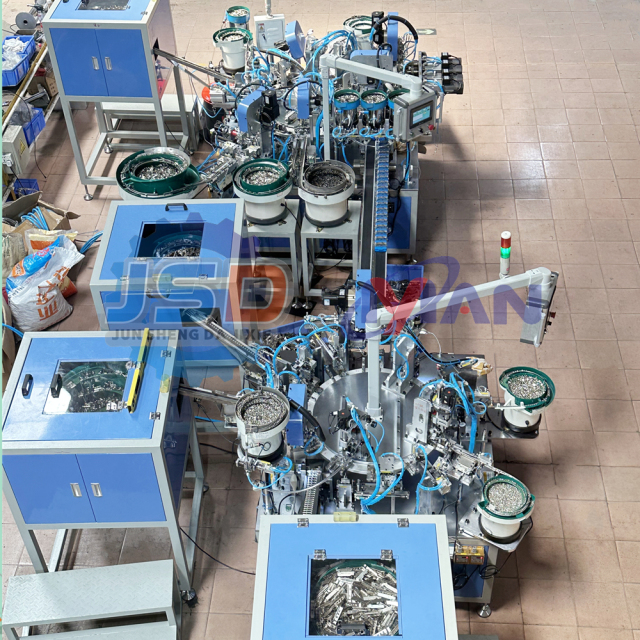

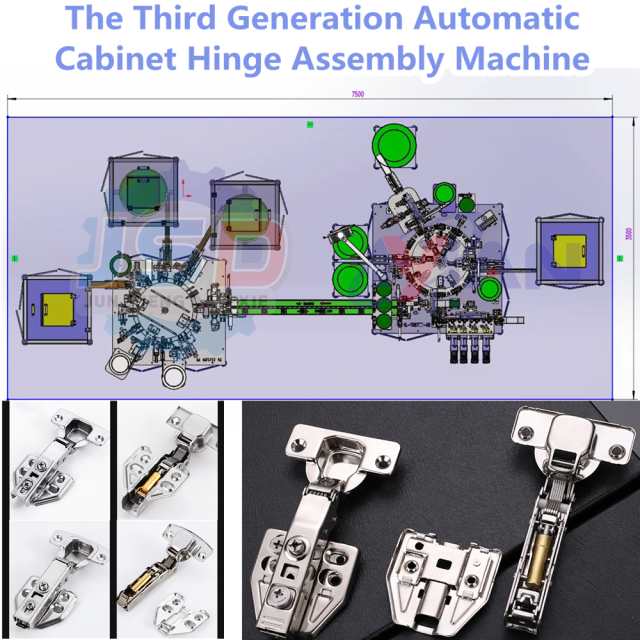

(1) The whole machine is small in volume and covers area, which can save a lot of site funds;

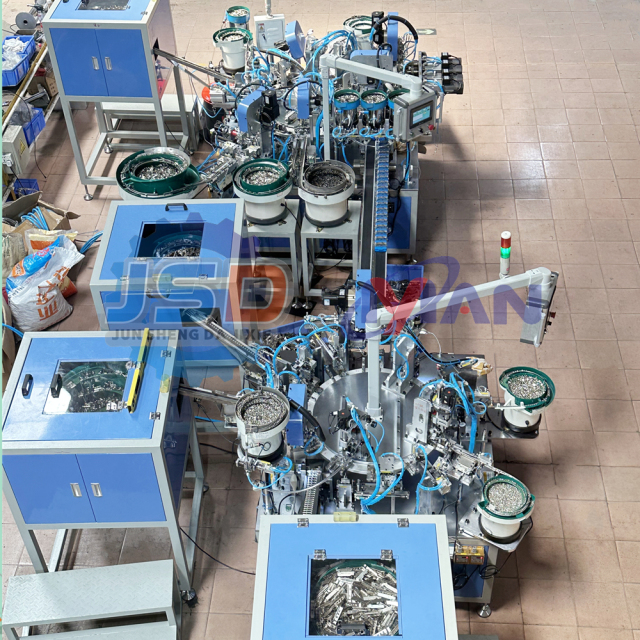

(2) The layout of the whole machine is reasonable, the vibration plate with large feeding noise is equipped with sound insulation cover, each equipment has transmission line buffer and separate outlet buffer between the port, such a layout allows the single machine in the line body can be used independently, can also be used online. Or when one of them needs to be repaired, it will not affect the operation of other equipment;

(3)The whole machine adopts the rotary structure, the thickness of the core component is 23mm, and the processing accuracy is plus or minus 0.0012, which makes the overall accuracy of the equipment higher;

(4)The whole machine adopts rotary structure mobile assembly fixture, flat belt transmission line transmission, and synchronous belt component transmission, can be generally assembled clip on and fixed type hinges.

(5)The electrical line layout of the whole machine is in strict accordance with our standards, the layout of all lines is reasonable, and the line end and pipe end are marked to ensure that the lines of each accessory have documented and drawings to follow;

(6)High-precision, using multiple sets of high-precision photoelectric induction system detection automata assembly;

(7)It can adapt to the two-shift working mode, using man-machine interface display operation, abnormal real-time tracking alarm, operation information at a glance;

(8) High-tech integrated production and assembly setting, systematization and integration;

(9) Flexible and flexible assembly customization scheme can adapt to a large number of batch generation tasks, or more quantity and less small-scale production requirements;

(10)99% of the whole machine assembly products are qualified.

2-Main equipment configuration list

|

Configuration |

Brand |

Configuration |

Brand |

|

Air cylinder |

Taiwan AirTAC |

Cylinder induction line |

Taiwan AirTAC |

|

Slicer |

China ZXB |

Touch screen |

WEINVIEW |

|

PLC |

Japan Mitsubishi |

Feeder |

China |

|

Riveting |

China |

Air pressure gauge |

Taiwan AirTAC |

|

Servo Motor |

Taiwan Delta |

Frequency converter |

Japan Mitsubishi |

|

Slide |

Taiwan HIWIN |

Oil Pump |

China |

|

Stepper motor |

RCON |

Magnetic valve |

Taiwan AirTAC |